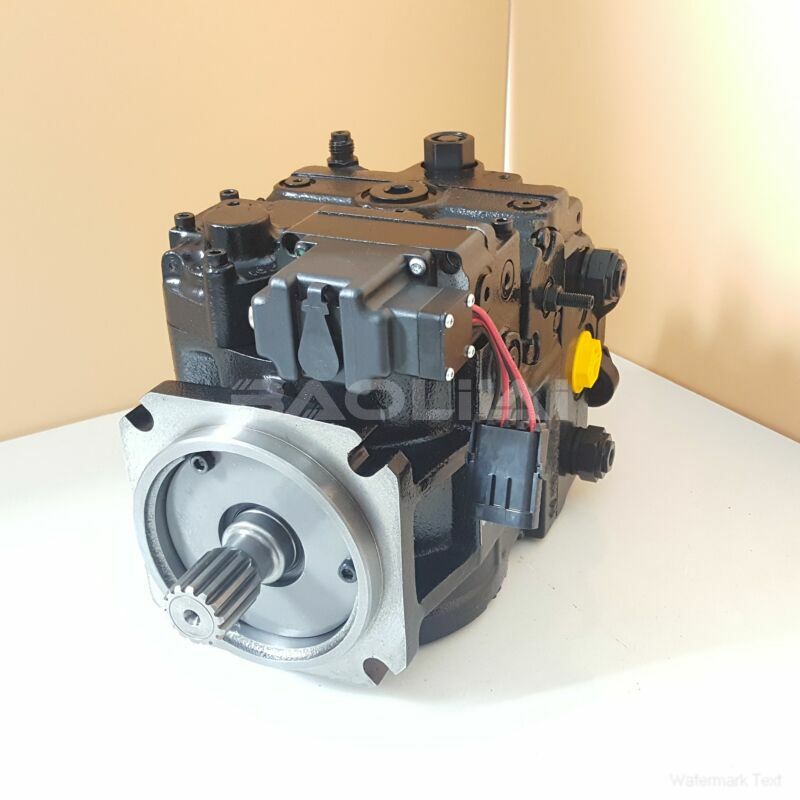

90L130MA5BC80S4F1FC5GBA171720 piston pump

90L130MA5BC80S4F1FC5GBA171720 piston pump

- Product Details

- Applicable Scene

90L130MA5BC80S4F1FC5GBA171720 piston pump.Hydraulic systems are essential in various industrial applications, particularly where high-pressure operations are required. However, one of the most significant threats to the longevity and efficiency of hydraulic pumps is contamination. Contaminants can lead to wear, decreased performance, and eventual system failure. This article will discuss strategies to prevent hydraulic pump wear due to contamination in high-pressure systems.

Model Code :90L130-MA-5-BC-80-S-4-F1-F-C5-GBA-17-17-20

Model Code :90L130MA5BC80S4F1FC5GBA171720

Understanding Contamination

Contamination in hydraulic systems can take many forms, including dirt, dust, moisture, and even particles from the hydraulic fluid itself. These contaminants can lead to abrasive wear on pump components, reduced lubrication effectiveness, and chemical degradation of the hydraulic fluid. It’s crucial to understand the sources and types of contamination to implement effective prevention strategies.

Model No.ldent No. :83003364

Implementing Proper Filtration

One of the most effective methods to prevent contamination is to utilize high-quality filtration systems. Installing filters at various points in the hydraulic system, such as upstream of the pump and at return lines, can significantly reduce the number of particles that reach the pump. Regularly checking and replacing filters is essential to ensure they function correctly and do not become a source of contamination themselves.

Seal Integrity

Seals play a vital role in preventing contaminants from entering the hydraulic system. Regular inspection of seals for wear, cracks, and other damage is necessary. Ensuring that all connections, including hoses and fittings, are tight and without leaks will help maintain seal integrity. If seals are found to be compromised, they should be replaced immediately to prevent contamination.