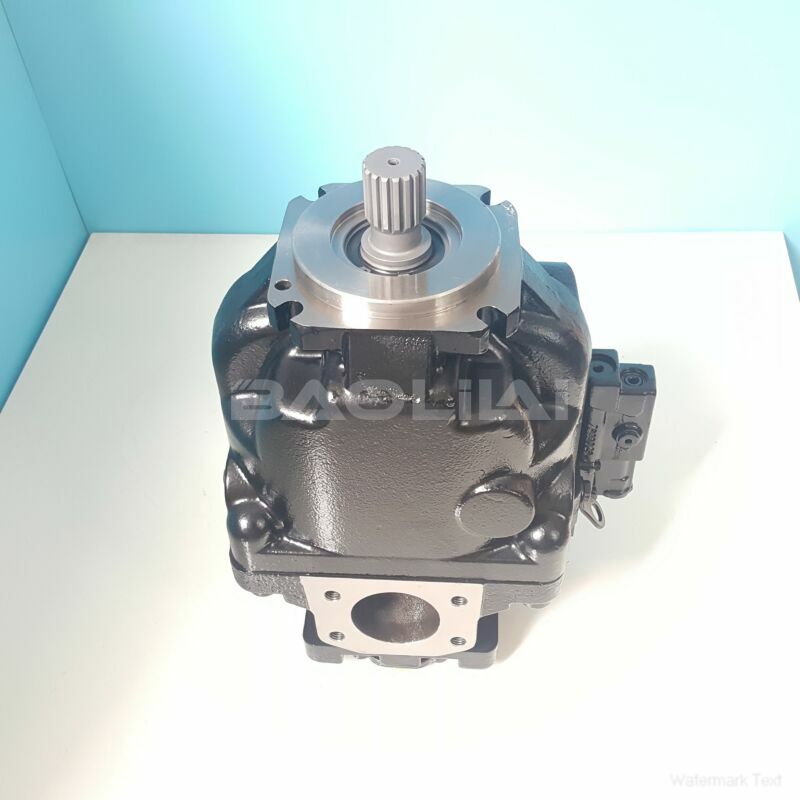

ERR100BPC21NNNNN3S1CPA1NNNNNNNNNN hydraulic oil pump

ERR100BPC21NNNNN3S1CPA1NNNNNNNNNN hydraulic oil pump

- Product Details

- Applicable Scene

ERR100BPC21NNNNN3S1CPA1NNNNNNNNNN hydraulic oil pump.Hydraulic pumps are crucial components in fluid systems, especially in heavy-duty applications such as construction, manufacturing, and transportation. When these pumps fail, it can lead to significant downtime and costly repairs. Understanding how to troubleshoot hydraulic pump failures can help identify issues quickly and restore system function. This article outlines common causes of pump failure and effective troubleshooting steps.

Model Code :ER-R-100B-PC-21-NN-NN-N-3-S1CP-A1N-NNN-NNN-NNN

Model Code :ERR100BPC21NNNNN3S1CPA1NNNNNNNNNN

Identifying Symptoms of Pump Failure

Model No.ldent No. :83015149

ERR100BPC21NNNNN3S1CPA1NNNNNNNNNN hydraulic oil pump.The first step in troubleshooting a hydraulic pump is to identify the symptoms of failure. Common signs include:

Noise: Excessive noise may indicate issues such as cavitation, aeration, or mechanical wear.

Pressure fluctuations: Inconsistent pressure readings could suggest blockages, leaks, or malfunctioning components in the system.

Reduced flow: If the flow rate drops unexpectedly, this may indicate pump wear or internal damage.

Overheating: Elevated temperatures can result from running the pump under excessive load, low fluid levels, or poor ventilation.

Leaks: External fluid leaks are a clear indication of seal failure or other integrity issues.

Common Causes of Hydraulic Pump Failures

To effectively troubleshoot a hydraulic pump, it’s essential to understand the common causes of failure:

Contaminated fluid: Dirt, debris, and water can compromise fluid quality, leading to wear and tear.

Improper installation: Incorrectly aligned or mounted pumps can lead to mechanical failures.

Overheating: High operating temperatures can damage internal components, resulting in pump breakdown.

Cavitation: This occurs when vapor bubbles form in the fluid and collapse, causing shock waves that damage the pump.

Worn components: Aging parts, such as bearings and seals, can fail due to prolonged use.