Lefort 269.32.43.01 Hydraulic Pump Mining Machinery A20VLO Axial Piston Variable Double Pump

Lefort 269.32.43.01 Hydraulic Pump Mining Machinery A20VLO Axial Piston Variable Double Pump

- Product Details

Lefort 269.32.43.01 Hydraulic Pump: The Robust Power Core for Demanding Industrial Machinery

In the demanding world of heavy industrial equipment, the reliability and efficiency of the hydraulic system are paramount to a machine’s performance and uptime. Lefort, a well-established European brand in hydraulics and engineering, provides durable power solutions for extreme applications across construction, mining, and more. Among these, the Lefort 269.32.43.01 Axial Piston Variable Double Pump (also referenced as model A20VLO hydraulic pump) stands out as a critical hydraulic component, engineered to deliver exceptional performance and durability for mission-critical equipment.

As a reliable supplier of hydraulic components, we offer high-quality parts including this model. For the complete technical datasheet for the Lefort 269.32.43.01 hydraulic pump, please visit www.baolilai-pump.com/contact_us/.

Superior Performance and Engineering Design

The 269.32.43.01 is a precision-engineered axial piston variable pump. Its design is optimized for long-duration, high-load duty cycles, with a core focus on maintaining consistent pressure and flow output under variable loads and temperatures while minimizing internal leakage.

Durability is at the heart of its construction. The pump housing utilizes high-strength cast iron, while key internal components like the piston/cylinder block and slipper/swashplate interfaces are treated with special processes for superior wear resistance and fatigue strength. This robust design ensures a long service life even in high-shock and continuous operation environments. The pump’s inherent resistance to pressure shocks, its contained design for safety in demanding conditions, and its effective sealing against moisture and contaminants make it suitable for the toughest job sites. This reliability is backed by a comprehensive one-year warranty.

Core Product Information

| Feature | Description |

|---|---|

| Product Model | Lefort 269.32.43.01 (Equipment Number) |

| Product Type | A20VLO Axial Piston Variable Double Pump |

| Primary Material | Cast Iron |

| Condition | 100% New |

| Warranty | 1 Year Warranty |

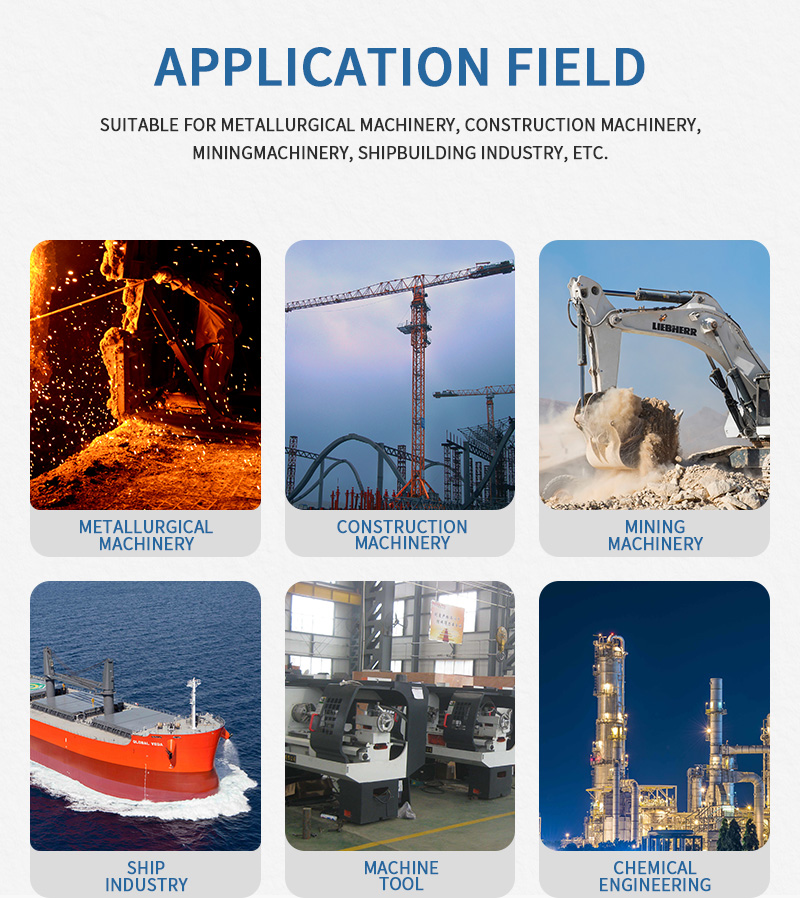

Wide-Ranging Applications

The power characteristics of this pump make it an ideal fit for Lefort equipment and other premium heavy-duty machinery across multiple severe-duty sectors. You can learn more about Lefort’s full range of equipment at their official site, lefort.com.

Construction & Earthmoving: In excavators, concrete pumps, and cranes, the 269.32.43.01 provides stable, controllable high-pressure flow for digging, pumping, lifting, and travel functions. Its variable displacement feature aids in energy efficiency and precise control.

Mining Machinery: Dump trucks, loaders, and drilling rigs require hydraulics that can endure dust, vibration, and shock loads. This pump’s rugged construction and reliable sealing are built for these punishing environments.

Agriculture & Forestry: High-horsepower harvesters, tractors, and forestry equipment depend on powerful hydraulics for complex implements. This pump ensures efficient operation in field and forest conditions.

Specialized Equipment: Equipment like port handlers, tunnel boring machines, and rail maintenance vehicles demand high power density. The compact dual-pump design of the 269.32.43.01 offers an efficient solution.

Frequently Asked Questions (FAQ)

Q1: What is the warranty for the Lefort 269.32.43.01 hydraulic pump?

A1: This product comes with a standard 1-year warranty from the date of purchase, covering defects in materials and workmanship.

Q2: What specific features contribute to its “pressure-resistant, explosion-proof, and extreme environment” capability?

A2: “Pressure-resistant” refers to its ability to withstand continuous high-pressure cycles. Its “contained design” houses all rotating parts within a robust casing for safety. “Extreme environment resistance” is achieved through sealing systems that effectively guard against external moisture, dust, and contaminant ingress.

Q3: What are key installation and commissioning precautions?

A3: For optimal performance:

- Ensure total system cleanliness using specified, clean hydraulic oil.

- Replace all hydraulic filters when installing a new pump.

- Check all hoses, fittings, and valves for leaks before startup.

- Bleed the system thoroughly and complete a no-load run-in before applying full load.

Q4: How can I ensure I am getting a quality replacement part?

A4: Source from reputable suppliers who can provide direct replacement parts with OE-compatible specifications and dimensions. Always verify the technical specifications and compatibility against your equipment’s service manual before ordering.

Specification

-2.jpg)